Israel-based DairyX is formulating cow-free casein protein micelles from Pichia pastoris, a yeast strain, using precision fermentation techniques. The method targets dairy cheese’s stretchy and protein-rich traits and using “simple inputs” like salts and sugars, the company genetically engineers the yeast to produce high-quality proteins.

The protein finds application in cheese, yogurt and non-dairy products like lactose-free and vegan dairy alternatives and offers the same functional and sensory qualities as their animal-based counterparts, says the company. It can also be used in specialized nutrition products as a clean label, animal-free source of protein to align with consumers’ sustainable and ethical food demands.

Food Ingredients First speaks with DairyX’s founder and CEO, Arik Ryvkin, for an overarching insight into the technology, benefits and applications of the process that helped the company train yeast “to produce the next generation of casein.”

“We are using Pichia pastoris, a yeast strain recognized as safe for food ingredient production by the FDA. It has been widely used to produce over 5,000 recombinant proteins, including biopharmaceuticals and industrial enzymes.”

“We chose Pichia because of its ability to grow to high cell densities and secrete large amounts of protein directly into the culture broth, which simplifies downstream processing.”

Our caseins are designed to self-assemble into micelles and gelate, just like in cow’s milk, says CEO Arik Ryvkin.The precision fermentation process leverages yeast as a “production platform” for bioengineered proteins, driven by proprietary ML-DOE algorithms and metabolic modeling, he explains. The team also used machine-learning models that simulated fermentation to determine optimal fermentation conditions.

Our caseins are designed to self-assemble into micelles and gelate, just like in cow’s milk, says CEO Arik Ryvkin.The precision fermentation process leverages yeast as a “production platform” for bioengineered proteins, driven by proprietary ML-DOE algorithms and metabolic modeling, he explains. The team also used machine-learning models that simulated fermentation to determine optimal fermentation conditions.

Mimicking traditional dairy with “smart casein”

DairyX has also refined a complementary technology which it says can enhance the gelation of its casein micelles, considered the “holy grail” of the industry.

“Our approach is simple: to capture the firmness, stretchiness and creaminess of traditional dairy cheese, you need to replicate how cow-made casein micelles are formed,” Ryvkin elaborates.

“In cows’ milk, caseins self-assemble into micelles, which then gel during cheese-making. We mimic this by creating what we call “smart caseins”— proteins with the same Post-Translational Modifications (PTMs) found in milk.”

These PTMs enable the caseins to self-assemble into micelles without the need for additives, capturing traditional dairy’s texture and functionality.

“Currently, manufacturers of animal-free dairy products use additives, like stabilizers, emulsifiers and thickeners, which don’t perform as well as cow’s milk and can be linked to unpleasant aftertastes. These fail to satisfy consumer cravings for a real dairy experience,” underscores Ryvkin.

Additionally, as protein ingredients, DairyX micelles have “no cholesterol or lactose,” which allows CPG companies to decide which fats and sugars to add to their formulations.

However, secreting casein from yeast was a “significant challenge since it’s notoriously difficult to express in other organisms, and there’s limited research available,” he tells us.

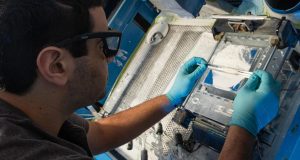

DairyX’s gelating micelles enable manufacturers to produce firm, stretchy and creamy products.“We faced issues at almost every stage — analytics, reconstitution, fermentation and even downstream processing. Ultimately, we solved these problems and developed IP that enabled us to achieve recombinant casein micelles stabilized by self-assembling caseins.”

DairyX’s gelating micelles enable manufacturers to produce firm, stretchy and creamy products.“We faced issues at almost every stage — analytics, reconstitution, fermentation and even downstream processing. Ultimately, we solved these problems and developed IP that enabled us to achieve recombinant casein micelles stabilized by self-assembling caseins.”

Costs and market penetration

Dairy’s proprietary process is currently a pending patent, Ryvkin states. The company uses an evolution-based approach to develop highly efficient yeast strains, which positions it to rapidly achieve price parity — and “potentially lower costs in a few years.”

Additionally, the company claims its yeast strains produce high casein yields in short timeframes. The approach ensures that DairyX’s ingredients are cost-effective, which it deems a crucial factor for adoption by dairy manufacturers.

Ryvkin also believes there is a growing interest in products derived from precision fermentation, with “multiple surveys, including the latest EU study, consumer willingness to try precision-fermented products has even surpassed interest in traditional and biomass fermentation.”

Notably, a recent German survey found that 57% of consumers would try precision fermented cheese, which supports this trend. While 24% were ready to accept it as a substitute for dairy cheese, 14% were willing to pay more.

However, he highlights “taste and price” as two key factors driving market adoption of these products, but expects significant improvements in the functionality of animal-free proteins as the industry matures.

“Prices will also decrease as new fermentation technologies and facilities emerge, alongside advances in biotechnology that allow us to better understand and manipulate microorganisms for production efficiency.”

Surveys depicts a rise in consumer willingness to try precision fermentation-based cheese.He also expects a rise in company collaborations, “combining expertise in both proteins and lipids” to replicate the total composition of milk more closely.

Surveys depicts a rise in consumer willingness to try precision fermentation-based cheese.He also expects a rise in company collaborations, “combining expertise in both proteins and lipids” to replicate the total composition of milk more closely.

Meanwhile, F&B innovators are making strides in formulating casein alternatives, with funding driving precision fermentation-related NPD to propel the sector’s growth.

Next steps

DairyX is currently focusing on improving the functionality of the micelle, making the yeast strain more efficient and scaling up, Ryvkin shares.

“The market is ready for cow-free products that are identical in taste, functionality and nutrition at a competitive price. We have validated this with several dairy manufacturers, who were eager to get samples for testing in the next few months.”

“We also initiated partnerships with several dairy companies and plan to advance these collaborations. Our initial focus will be on co-developing technology and products with our partners over the next few years,” he concludes.

The company also recently launched a pilot project with a start-up to upcycle biomass from fermentation, aiming to reduce waste, benefit the planet and save costs.

You can now read the most important #news on #eDairyNews #Whatsapp channels!!!

🇺🇸 eDairy News INGLÊS: https://whatsapp.com/channel/0029VaKsjzGDTkJyIN6hcP1K