However, the fast growing population and the ubiquitous movement of people away from rural farming areas mean the fewer farmers will either have to increase the amount of milk each cow produces or improve efficiency in milk production.

Keeping the cows happy and healthy is important in dairy farming and efforts to raise the bar in milk production efficiency require farms to know how much an individual cow eats, how much she drinks, how much she moves, her body temperature and stress levels so as to correctly judge farm profitability and top performing cows for breeding purposes.

Technology has been the main driving force in bridging the intelligence and efficiency gap although it may not seem apparent but new technologies involving sensors and big data analytics are making farms approach light speed efficiency in how they operate.

There’s currently a huge influx of big data through sensor in the agricultural economy.

Sensors are what recognize cows through their spot patterns, internal and external behavior, nose print, width between the eyes, placement of the ear tag, or the length of their head. Information gotten from hundreds of these sensors can then be processed for autonomous machine control that matches each individual animal. Examples includes a tractor connected to an online mapping system to harvest overgrown hay, moisture precision devices placed amidst crops that can detect sunlight levels, pest pressure in the environment, water and nutrient levels. Ill cows can be easily spotted while grazing

Here are some modern gadgets and devices that will aid in boosting milk production and herd management:

Robotic cow milking equipment

“This multi-million dollar technology is by far the most well-known application of robots in the dairy industry,” said Chen Yuanrong, the founder and chairman of Blue River Nutrition. “It not only milks the cows, but it also washes, massages and feed cows.”

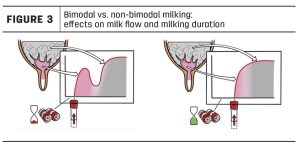

Whereas prior to robots, cows were only milked twice a day due to time and labour constraint; with robots, companies like Delaval robotic milking system and miRobot, provide milking systems that are able to milk multiple cows simultaneously while maintaining a clean and sanitized environment to keep the cows in healthy comfortable shape. Cows seem to enjoy getting milked three or more times as they often go back on their own free will.

Use of drones

Through aerial monitoring of land and cows grazing, farmers can respond immediately to emergencies and possibly save the life of crop or an animal. With development in battery life and autonomous flying ability, drones will be able to map, inspect/survey and photograph pasture areas where growth has been detected suitable for cow grazing.

Rotating swinging cow brush

Used for almost a decade. This is a simple rotating brush similar to one used in a carwash but made specifically to match the contours of a cow’s body.

It rotates at a comfortable speed that cows love and often queue to be next in line to use this massager. In an effort to boost cow’s comfort, research shows the rotating cow brush aid blood circulation which in turn improves milk production and child birth

Collar technology

An ID collar that sends information to the farmer through a transponder to keep track of cow’s health, milk production levels, milking frequency and how much activity the cow is getting vs. how much the cow is eating. This wearable technology is vital in individual cow management as it allows farmers to detect cow’s welfare and quite possibly respond before milk production or the herd is affected. SCR Diary is a market leader in the area of animal wearable technology which can be worn on ears, neck, legs or tail.

3D Printing

There are a multitude of applications of 3D printing in the dairy industry. A primary application is the replacement of machine parts in rural farmers will not only save valuable time but also money.

As 3D printers become more and more accessible, research is ongoing to re-engineer dairy products cutting out the use of cows itself. This means milk consumption which has been dwindling in countries like US and UK due to deficiencies such as lactose intolerance can be reversed and there will no longer be any reason to avoid it.