Hocken was a self-confessed “city girl through and through” when she and husband Mat returned to New Zealand in 2013 to run the Hocken family’s 1000-head dairy farm in the Manawatu.

“Farming was absolutely new to me but I was soon seeing the same kinds of things I’d seen in other industries I’d worked in overseas – a lot of wasted movements, the same problems cropping up again and again but not being solved, people doing the same thing in 10 different ways and still not achieving the desired outcome.”

She knew the Lean thinking and methodologies she’d introduced to scores of companies and organisations in Europe, US and Australasia – in banking to IT, manufacturing to health care and even a Navy – could also be applied down on the farm.

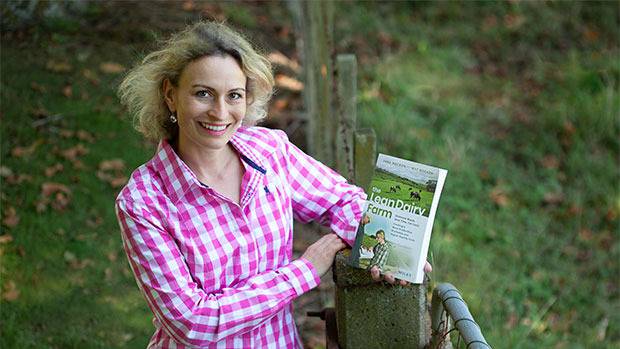

Hocken’s recently released book, The Lean Dairy Farm, outlines with humour and plenty of real life examples drawn from the family farm, how Lean can reduce costs, save time and boost quality, and just as importantly for farmer owners and their staff, cut stress, frustration and work hours.

Lean is not some exercise programme but it is about shedding the unnecessary. It’s a set of principles and practices underpinned by a philosophy of continuous improvement, and relentless, systematic elimination of anything that wastes time and resources.

Hocken’s Lean journey started when she studied industrial engineering at university – “optimisation techniques, time efficiency studies and all that sort of stuff”.

Hocken wasn’t originally thinking of a career in that space but Melbourne at the time was still a big automotive city, and she joined Toyota’s graduate programme.

“The Toyota Production System is actually Lean, it’s where the Lean concepts come from.”

As she notes in her book, in the 1940s Toyota was languishing when compared with General Motors in the US. But borrowing from Henry Ford, and from the practice of supermarkets to create flow of product ‘Just in Time’ by restocking their shelves based on customer demand, Japanese engineer Taiichi Ohno developed the Toyota Production System (TPS), propelling the company to No 1 internationally.

The authors of a 1990 book about Toyota, The Machine that Changed the World, described TPS as “lean production”, a management approach that has since been adopted by almost every industry sector and any type or size of business on the planet.

“As soon as you start at Toyota you become integrated into this way of thinking,” said Hocken.

“It just becomes you. It’s the DNA of the company and it’s the way you learn to work, to think and how you do things.”

After several years’ work in Australia, Hocken went to Belgium to become a TPS specialist focusing on engines and transmissions, helping suppliers as large as Bosch to get their systems into Lean mode and achieve the right quality and delivery expectations Just in Time into Toyota.

She branched out to become a Lean consultant to myriad other industries but by then she had met a fourth-generation Kiwi farmer who had been working overseas in international policy circles.

Fast forward to the Manawatu, on a winter night.

Hocken woke at 1am and Mat still isn’t home. She phoned him several times but there is no answer. She put on her dressing gown and crocs and drove over to the shed to find him trying to help a cow to calve.

“He asked me to go and find the calving pulley that was apparently somewhere near the platform at the other shed. So I drove around to the other shed – there I was running around a shed at 2am, in the rain and wind, six months pregnant, in my dressing gown like a mad person looking for some pulley (and I didn’t even know what that was). I remember thinking ‘This is just ridiculous; how on earth isn’t there a standard place for this thing so it can easily be found when you need it’?”

In the end, Mat had to improvise using ropes around a fence rail but the story is a good way for Jana to introduce her chapter on the 5S system (sort, set, shine, standardise, sustain).

In fact, her 400 page book is peppered with examples of dairy operation pratfalls and staff frustrations as Hocken introduces Lean techniques such as visual management, red tagging, value stream mapping and error proofing.

If one accepts the definition of waste as anything that doesn’t add value from the end customers’ point of view, Jana says as much as 95 per cent of what happens on farms (and indeed many other industries) is wasted effort.

Reasons range from overcomplicated or inefficient processes, failure to ensure each team member understands the farm status and plans, to spoiled inventory and non-standardisation.

Hocken agrees with the comment that lots of her remedies seem like common sense.

“So why aren’t we all doing it!,” is the obvious retort.

“That’s the beauty of lean methodology. It’s simple, practical stuff that pretty much anyone can do. It’s used successfully by hundreds of thousands of businesses worldwide but you need to know how to go about putting it in place, and sustaining it.”

Hocken believes too many businesses think they can best add to the bottom line by introducing flash new technology.

“Of course it can help, but if new technology and equipment is just dumped on top of poor processes, the owners often end up wondering why they’re not getting the results they anticipated.”

Particularly tricky is achieving the “cultural element” – getting staff on board with different ways of doing things, and making that stick long-term.

In many ways Hocken’s book is a manual for farmers to open up conversations with their staff.

“That’s probably one of the weaknesses in farming,” said Hocken.

“A lot of other businesses have quite a focus on work culture, and they might have an entire HR department.

“Let’s be honest, that’s one of the reasons people get into farming. To be outdoors, to get away from people and their problems. But dealing with people is becoming more and more part of our business and is vital.

“The ability to engage people around you and get the best out of them – that’s a challenge.

“Agriculture already has employee retention issues. If we find ways to get our employee’s ideas and feedback, making it a two-way process instead of top down, it does wonders for everyone’s job satisfaction.”

Hocken wrote the book after positive feedback from workshops with 100 farmers she ran in New Zealand two years ago.

She’s now in the middle of running Lean workshops for Dairy Australia in Tasmania, with the prospect of also rolling it out to Victoria and Western Australia.

The Lean Dairy Farm is on worldwide release and Hocken is enjoying the letters and emails coming from overseas.

“There are farmers in Ireland who absolutely love Lean! I often get asked whether this is just for big farming operations but Ireland demonstrates that’s not so. The farmers there often have herds of 50-100; many of them are husband and wife businesses but they see what Lean can do for them.”

In a way, Lean principles are even more relevant for smaller operators, she said.

“Probably one of our biggest battles on the farm is the long days. When you realise that so much of the frustrating stuff that happens could be avoided in the first place, with better processes and so on, we can get that better work/life balance.”