Dairy farms come in all sizes and shapes, from mega farms that are found mostly in the West to the small ones tucked in many areas of the Northeast and elsewhere.

Surviving as a dairy farm can be challenging with all the variables that are presented every day. Seeing how some folks are meeting the challenge and determining their own destiny has always fascinated me.

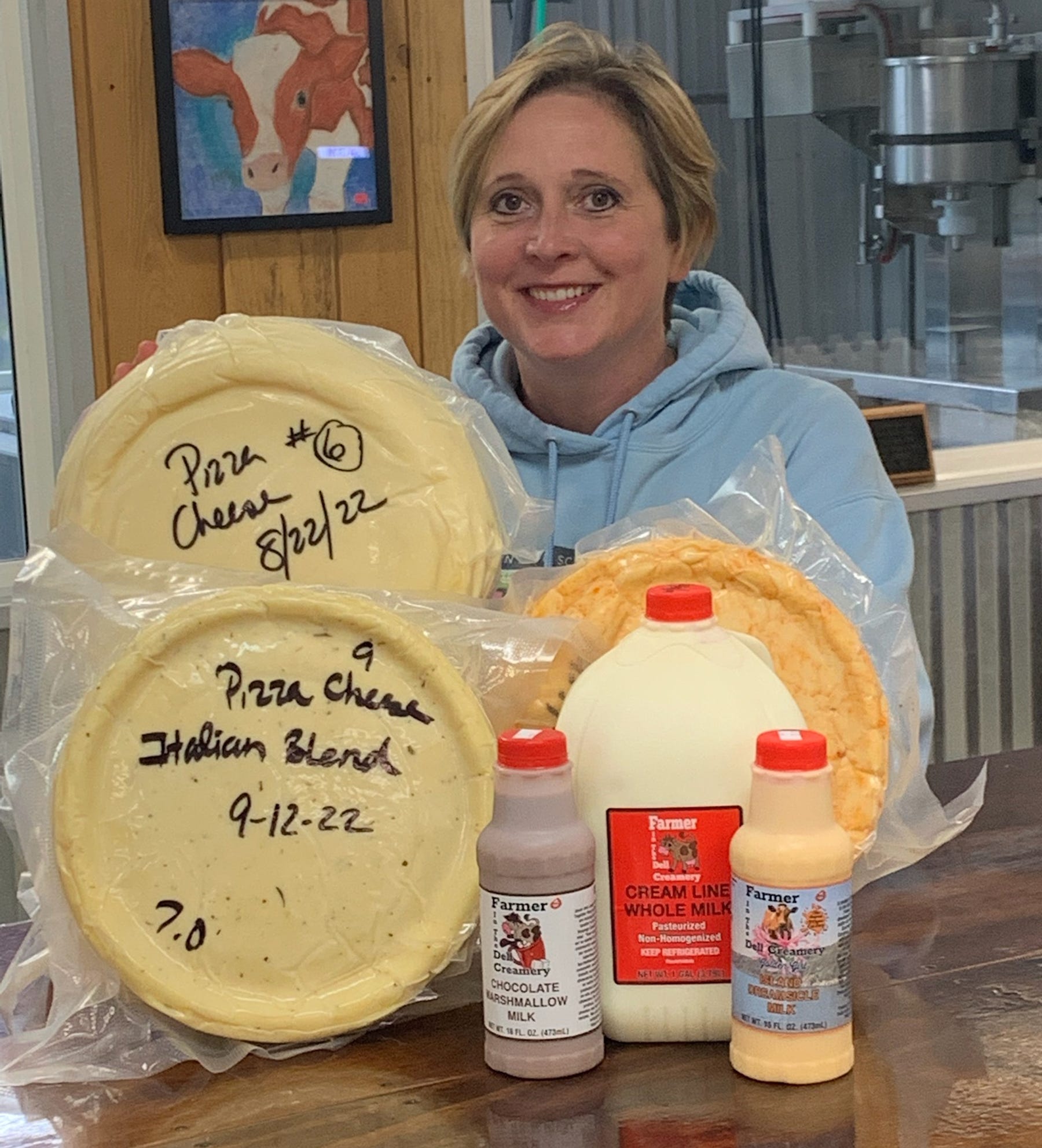

Recently, I visited with Jessica Kennedy to learn the story of how she and her husband, Jason, started selling milk from their cows through a pizza shop.

When the Kennedys moved to their farm in 2007, there were no decent pizza shops in the area. With a young growing family, this prompted Jessica to begin a long-researched project that resulted in her deciding to create a value-added product from their milk to help stabilize their income.

A small storefront in nearby Cooperstown, Pa., sat empty for quite a while. Jessica contacted the Pennsylvania Center for Dairy Excellence and got a professional adviser to help them move from being a farm to running a processing plant and retail outlet in this small building.

She found that there were 7,000 mailboxes in the area. To her, this meant that there was potential for a lot of customers like herself who would like good, local pizza, as well as access to locally produced milk and other dairy products.

Cheese curds are another product they sell. The fried cheese curd is a popular item in their pizza shop, Farmer in the Dell. They are also creating new milk flavors. The newest one is Strawberry Pretzel Salad in honor of their Red and White Holstein cows.

Both Jason and Jessica have worked very hard to make their farm a success. Now, they have a small restaurant where they can sell their amazing cheese, ice cream and milk to their neighbors.

What started as a dream has become a reality. Jason and Jessica have four children who are involved in 4-H, showing dairy cows. The couple have Brown Swiss, Milking Shorthorns, Jerseys, Holsteins, and Red and White Holsteins.

As they look toward the future, they are considering reducing the size of their milking herd so they can sell all the milk they produce through the retail outlet.

Other dairy families have found ways to incorporate adding value to the milk they produce to help stabilize their bottom line.

The Henry family of Knox, Pa., have put in a processing plant on their farm where they not only sell their own milk, but also stock milk products for small grocery stores and other on-farm stores in the area.

A few years ago, the Henrys started breeding their cows to bulls that carried the A2 gene that is desirable in milk. A2 milk is considered more easily digestible than typical A1 milk.

The Henrys pasteurize their milk, but they don’t homogenize it. The cream rises to the top and customers are reminded to shake the bottle to incorporate the cream before they pour a glass.

They have been very pleased at how the community has supported their efforts.

Another local family near me, the Canons, have built a small processing plant and retail outlet on their farm to have two of their children return to the business. They regularly have whole and chocolate milk available, and occasionally make other flavors.

Josie, one of the Canon children, makes cheese curds in several flavors that are popular with customers.

Not all farms or farmers are able, or want, to continue getting bigger and bigger.

Instead, they are finding more creative ways to deal with the volatile milk market and securing their farms for the future.