Livestock producers are always looking for ways to get their products to market in the most energy, labor, and cost-efficient ways. For dairymen Rick Heuer and Jim Dieball, the tug-o-war is no different, but their weapons of warfare are. Rick Heuer of Heuer Farms in rural Lester Prairie, Minn., and Jim Dieball of Dieball Dairy near Green Isle, Minn., have invested in robotic milking systems.

Heuer Farms retrofitted their tie-stall barn to accommodate a robot, whereas Dieball Dairy decided to go the new construction route. I had the opportunity to catch up with each of them to compare and contrast the advantages and disadvantages of their building preferences.

Dieball Dairy

Jim Dieball is a third-generation dairyman. He grew up on the farm, went to college, and returned after two and a half years. “It’s all I’ve ever known. It’s all I’ve ever done,” he reflected. “[But] if the robots weren’t here, the cows wouldn’t be here,” he added. So Dieballs went from milking in a parlor to the robotic milking system, which has been for the better.

In 2018, Dieball Dairy installed three Lely A4 robots into their newly constructed free-stall barn. Their previous free-stall barn was nearing 45 years old, and a shift needed to happen. “We looked into utilizing that [old] barn with the robots, but the layout didn’t work,” he said. Plus, they were going to need a facility for heifers. So Jim and his wife Wendy, along with his parents Karl and Rosemary, decided a new barn for the cows was the better option. “It was, pretty much, build a new barn or plan an exit strategy,” he said.

Dieballs now house heifers in the old free-stall barn, dry cows in a hoop barn, and the milking herd in a new free-stall barn. Since building the new milking facility, Dieballs have also increased the herds’ size. Jim said they went from milking 120 in the old barn to milking 204 in the new facility. “We mostly grew from within. However, we did purchase a few animals,” he said.

In discussing the cost efficiency of the new construction, Jim confidently stated, “Typically, the money is in the dairy cows, not the heifers. You have to have a decent place to raise your heifers; but I know we wouldn’t be getting the same [milk] production in the old barn as we are in the new.”

Not only did Dieball install the robots, but they also made significant cow-comfort changes. In the new barn, they went with sand bedding, automatic ally scrapers, headlocks, drive-by feeding, and cross ventilation. “The sand bedding was the biggest change,” Jim noted as we talked about cow-comfort changes. “The cows really like it,” he added.

The sand bedding has brought challenges, however. Dieball said handling the sand and figuring out how to clean out their manure storage pit has been a learning curve. “The first year, we were stubborn and thought we could just pump [out the pit]. But we’re learning, and now we have a system figured out, and it works very well for us,” he added.

A higher cell count, attributed to the sand bedding, has also been a challenge for Dieballs. “There again, we’re still learning,” he said. Dieballs have started grooming the beds more often, Jim said. And as their herd grows, Jim said he would like to do more selective culling, getting rid of the high cell count cows faster. “We’re still in expansion mode, so we’re not culling all of the high cell count cows because we don’t have the replacements yet.”

Regarding production, with the installation of the robotic milking system and the cow-comfort upgrades in the new barn, Jim said that production is up. “Production is up 14 to 15 percent. We were at two times per day milking [in the old parlor], and now we’re up to 2.7 times per day,” he shared. “Our components are up, hoof health, and feet and legs are much better, too. It’s just way, way better for the cows.”

With increased cow comfort in the new barn, Dieball is seeing better production and reproduction. “Pregnant cows, at the right time, are profitable cows,” Dieball stressed. “We use activity monitors and the G6G synchronization program,” he said.

Jim said that the combination of a well-managed synchronization program, activity monitors, and the less stressful and more comfortable environment all attribute to increased conception and reproduction.

“Milking in a parlor in extreme conditions is very unpleasant, and it takes more time,” said Jim. “Having the robots is still work, but it’s more management. Now, one person can manage if events are going on or if there is other field work to do. I can come out and do chores at 10 o’clock at night; the cows don’t care! As long as they have feed and the robots are working.”

Another perk of the new construction is Dieballs have the option to add on to the barn. Jim and Wendy’s daughter Aly is very interested in returning to the farm after she completes college, while their younger daughter Shelby will pursue a degree in early childhood education. Jim said they do not have any plans for expanding yet; they’ll wait and see what the future holds. However, Dieball is delighted with their decision to invest in a newly constructed free-stall barn and the installation of the robotic milking system.

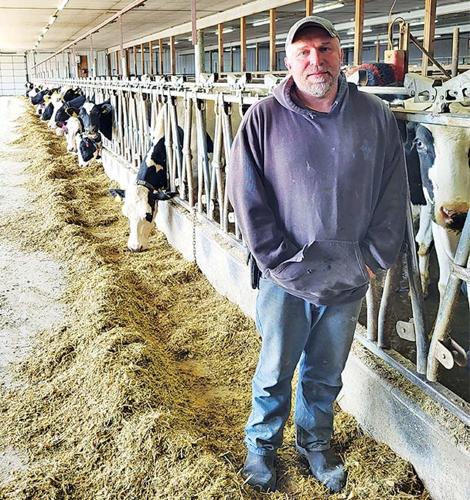

Heuer Farms

“I’ve been milking since I was 15,” recalled Rick Heuer of Heuer Farms. “My dad died, so I milked through high school with my brother. My brother, who is a year older, is on the home farm, and he’s still dairy farming,” added Rick.

After a short stint away from rural life, Rick returned. “I just didn’t like the city. So I bought a herd of cows and rented a barn,” he said. In 1995 he purchased a farm of his own and has been there ever since.

From 1995 until 2022, Rick, who does all of the milking solo, was up and down milking two times per day in a tie-stall barn. “I was thinking of quitting milking. My body was getting worn out. But at the last hour, I decided to put in a robot and keep going,” Heuer said.

His reason for putting in a robot is pointed, “If I milk until I’m 66, then want to quit, I can sell the robotics yet.”

Heuer installed one Lely A5 robot into his existing barn, which he retrofitted to house 60 cows. “I gutted the barn,” commented Rick. Only the shell of the building and the manure storage system remained the same.

At the start of the barn renovation, Rick added a new milk house and a maternity and calving pen with headlocks. He said he used the maternity pen for milking for two months while the rest of the barn was retrofitted and the robot was installed. “The [milking] cows were housed in the dry cow barn during that time. It was a long two months!” he laughed. “It was terrible!”

In the retrofitted barn, Rick now has 38 headlocks and 51 free stalls. “Obviously, they can’t all eat at once, but with a robotic barn, [the cows] are all doing something different anyway,” Rick stated. “With a parlor, that wouldn’t work; you would need more headlocks. But it’s working here.”

He also installed water beds for cow comfort, which he grooms daily, adding dehydrated lime or sawdust. “I still have my exercise lot,” Rick said. That’s where the cows go while he grooms stalls; and even then, the cows have access to the robot.

At first, the new stalls were a challenge, attributing to a higher cell count. But Heuer said it is coming down. He has learned it is helpful to let all of the cows into the exercise lot and empty the barn once per day. That way, he can sweep the mangers and groom the stalls, giving the cows a clean slate every day. Rick said his cell count is still slightly higher than it was before switching to the robot. “But now, I know [which individual cows] are high. That helps.”

In addition, the Lely robot gives individual cell count readings for each milking, which helps Heuer monitor those cows more closely.

Currently, Heuer’s herd is milking three times per day with the robot. “Production is up 15 to 20 pounds,” he said of his herd. Heuer’s cows give 90 pounds of milk daily, and he hopes to hit 100 pounds as he freshens more cows.

“What I really enjoy is the activity monitors!” Heuer said his herd had always been on shot synchronization programs for breeding. “Now, I very seldom give a shot. The activity monitors are very accurate [for heat detection].”

In addition to adding the robotic milker, Heuer added a robotic manure vacuum. The manure vacuum runs slowly up and down the ally doing exactly what one would think: it vacuums the manure. It then empties itself into the manure pit.

One of the main reasons Heuer retrofitted his barn, besides preserving his body, was the location. “I kind of like that I can come out in my pajamas and push in feed,” he said. “It’s close to the house, and I liked where the barn was. This way, if it’s the middle of the night, I can come out if needed. With cows, you need to be here anyway.”

Heuer also likes the flexibility the robotic milking system offers. He no longer has to stop field work or decline social invitations because it conflicts with milking. With the robot, Rick can fetch the two or three cows that need to be reminded to get milked a little earlier or a little later. “I’m not tied down to four hours of chores in the middle of everything. It’s really convenient that way,” he said.

Both Dieball and Heuer agreed that dairying is in their blood. “Sometimes I wish it wasn’t,” Heuer joked, “but I guess it is.” So, the cows stayed at both farms, and the love for the industry continues to thrive.