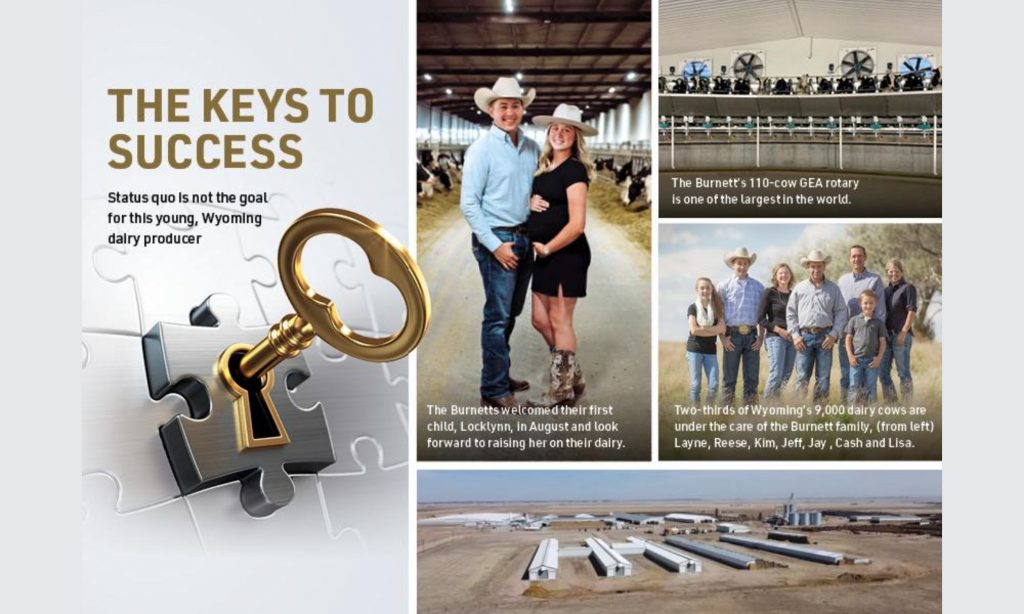

Generally, you don’t think of dairies. Although, travel to Carpenter, Wy., and you’ll see two-thirds of the state’s 9,000 dairy cows, who are milked at Burnett Dairy. You’ll also get to see an upcoming second-generation dairy farmer, Reese Burnett, who simply couldn’t imagine his life anywhere else, but in his home state of Wyoming, milking cows along with his family for a living. Reese’s goal is to not let grass grow under his feet, as he is enthusiastic to help drive his family’s dairy forward.

Unique Upbringing

Reese’s grandparents had a small cow-calf operation, along with dryland wheat, an hour north of Greeley, Colo. The family farm grew and diversified, including custom feeding cattle and running small feedlots. In the early 2000s, when mad cow Disease hit, the Burnetts were challenged with finding customers for their feedlot that forced them to change direction.

“This is what pushed my parents into the dairy business,” he says. “They started by renting a neighboring dairy in 2004, milking 200 cows. A year later they started Burnett Dairy and today milk 6,200 cows in a 110-cow GEA rotary.”

Reese left Wyoming and headed to Kansas State for college in 2018. When he returned home to the family farm, he spent a lot of time on genetics, herd health and nutrition. Over time, he has added additional responsibilities, including sharing the employee management.

“I’m very fortunate. My mom and dad and uncle have given me a lot of freedom in my work and have really allowed me to take off and do some fun things with our dairy,” he says.

For example, Reese quickly saw that milking the entire herd 3x a day was too much for the parlor to keep up with. He recommended milking more cows and shared that the majority still could get milked three times a day, with the remainder twice daily. Running 22.5 out of 24 hours and shutting down twice a day for a wash cycle, Reese shares that now the parlor is running at capacity.

Challenges Presented

Like many dairies, Burnett Dairy is no exception to challenges. Weather extremes—going from 95-degree summers that require irrigation to grow crops to sub-zero temperatures in the winter challenge Wyoming farms. Reese says that the dry heat is tolerable for the cows. Winters can be especially brutal, as he shares this past winter dropped 40 degrees in 30 minutes.

With Cheyenne an hour away, the Burnetts house all their employees, as it is too far away to commute them to work. With the magnitude of the dairy shipping seven semi-loads of milk each day and the new technology of the carrousel, including the two robots in the entry that pre-dip and clean teats, as well as a robot on the back side of the deck that sprays a post-dip, the family has become savvy at diagnosing problems, as a service call is timely.

Working With Family

Reese could never imagine not working on the family dairy farm. The discussion unfolded about him coming back to the operation, but the family knew 3,000 cows wasn’t going to be sustainable for them to support another family member. This is what spurred the expansion in 2019.

Although for Reese to come back to the farm, there were two requirements—obtain a four-year degree and work for someone else.

“We never had a sit-down meeting, but Dad and I would ride in the pickup, and we’d bring up the conversation and visit about it,” he says. “The biggest key was establishing trust from both sides.”

Three summers during college Reese found somewhere else to work, conducting internships with Royal Farms Dairy, a 6,000-cow dairy in Garden City, Kan., and Dairy Nutrition Management Company based out of Fort Collins, Colo., and WinStar Genetics in Shelley, Idaho, where he learned more about how to ultrasound cows.

“I think it’s super important to go see other dairies and get experience working on other farms,” Reese says, sharing that his experience working for Royal Farms Dairy outlined the importance of being disciplined to maintain details.

“If you want to be an above-average dairy, you have to pay attention to the details. And make sure even the smallest details are 100% every day,” he says.

His father agreed that three internships gave Reese a wealth of experience despite the original plan for Reese to work somewhere else after graduating college. He returned home in December 2021, as the dairy was quickly growing and there was now a spot for Reese.

Growing from milking 3,000 cows in a double-35 parallel to milking 6,200 in a 110-cow rotary, Burnett Dairy saw considerable changes that unfolded while Reese was away at college. The young Wyoming dairy producer shares that most of his ‘real’ education came after graduating college.

“I think that education is super important. I think college gives you a good foundation of science and why we do what we do. But the real education comes after school when you say, ‘Alright, this is what I learned in school, and how can I apply that every day on the farm,’” he says.

Reese shares that it took a lot of humility coming back as the owner’s son and being a recent college graduate.

“I pictured myself spending a lot of time managing cows and less time managing people,” he says, sharing that he understands you cannot be complacent about being good and must be driven to better yourself and your business. He underscores a key to success can be found outside of the farm office and in the barns.

“It’s good to have ownership on the ground with the cows,” he says. “That’s something I never want to lose part of.”

Future Plans

Burnett Dairy doesn’t plan to increase size right now, but they are breaking ground on three new calf barns to give them enough room to raise their beef-on-dairy crossbred calves. The family sees a continued value-added profit line in raising these calves and Reese shares that they plan to raise them all the way to slaughter.

While technology is intriguing to Reese, as his parlor is one of the largest rotaries in the world, he cautions other young producers not to put the cart in front of the horse.

“Don’t adopt the technology before it’s ready,” he says. “The biggest thing that my family looks at before adopting any technology is understanding how it will help our bottom line.”

The best piece of advice Reese offers to new graduates who are returning home to their family dairy is to have patience.

“Be patient with your time, be respectful to of all the years and service that the employees there have put in there,” he says. “You can learn from them, too.”

Glory to God

While managing cows and employees occupy a lot of Reese’s time, he says his biggest key to success is having a very faith-focused family.

“Family and God are our number one priority,” he says. “Being able to work together with family has allowed us to grow as much as we have these last couple of years.”

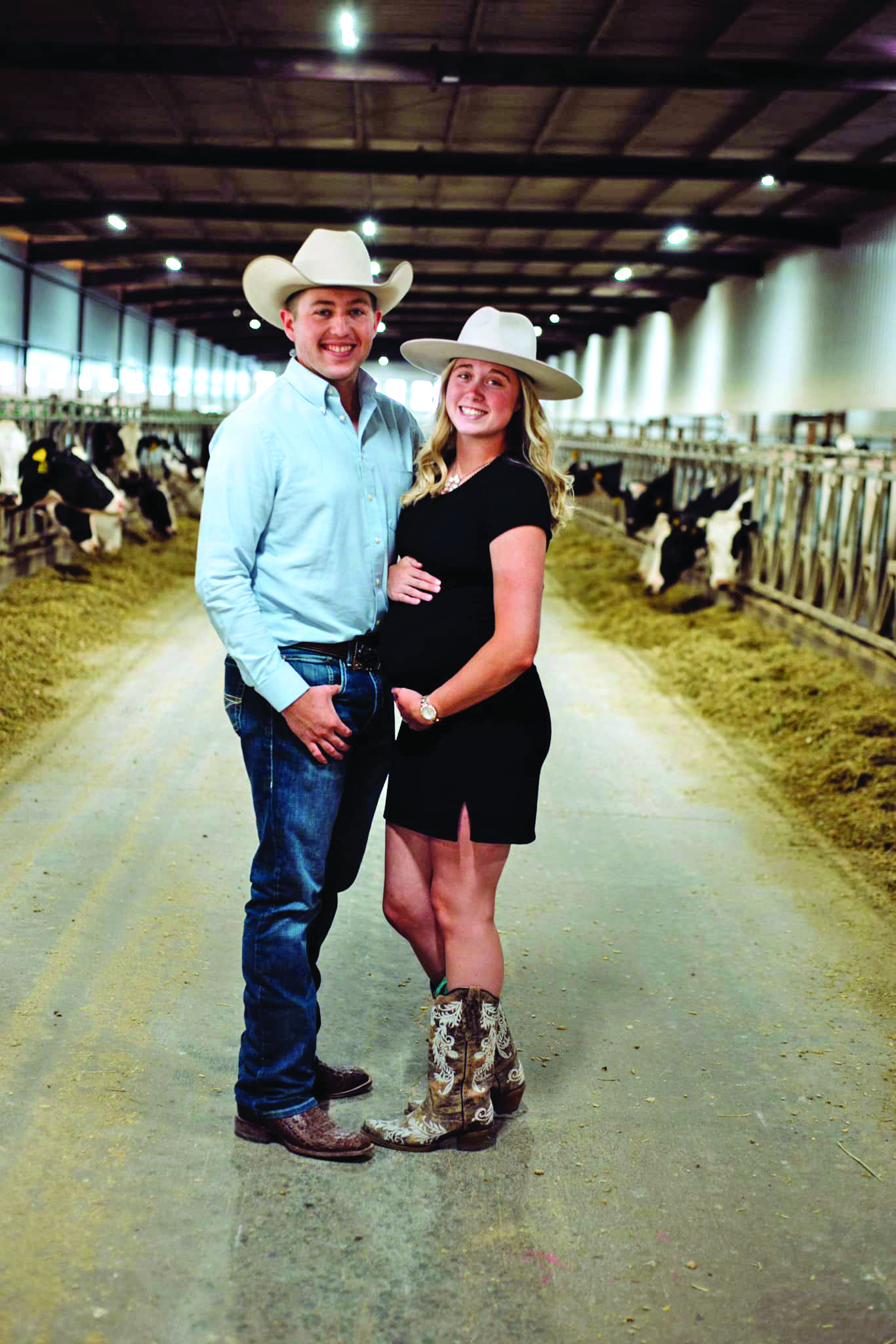

Reese and his wife, Hannah are expecting their first daughter in August, and they are excited to raise her on a faith-based family dairy farm.

“I loved growing up on my family farm. I was four years old when we started milking cows and I just have so many good memories working on the farm with my father,” he says.