The cheese and dairy industry is undergoing a seismic transformation in 2025, driven by advances in automation, artificial intelligence (AI), robotics, and evolving labour dynamics. With the UK’s post-2024 budget updates—particularly changes to National Insurance contributions—and rising minimum wages, the sector faces growing financial pressures that are reshaping operations and strategies. At the same time, the cheese production segment is responding to shifting consumer demands, including a heightened focus on sustainability. This article delves into these transformative forces and examines their implications for the industry.

Trends in Cheese Production

Cheese remains one of the most dynamic and profitable segments of the dairy industry. Growing consumer demand, an emphasis on premium products, and expanding export opportunities are driving the sector forward. However, these opportunities come with challenges, including supply chain pressures, innovation demands, and an increasing focus on sustainability.

Premiumisation and Consumer Trends

Premiumisation is a dominant trend shaping the cheese market in 2025. Consumers are willing to pay a premium for high-quality, innovative, and artisanal products. Hot-eating cheeses such as halloumi, and functional cheeses fortified with protein, probiotics, or other health benefits, are experiencing particularly strong growth.

This consumer appetite for unique, high-value products is encouraging cheese producers to innovate. Offering diverse flavour profiles, creative pairings, and health-focused formulations is becoming essential for staying competitive. Producers who focus on differentiation and quality are well-placed to capture market share in this expanding segment.

Supply Chain Challenges

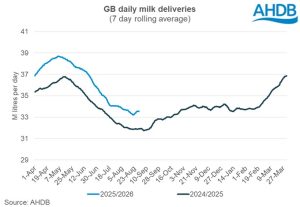

Despite robust demand, supply chain issues remain a persistent challenge for cheese producers. Factors such as reduced milk production—driven by environmental regulations, climate change, and disease outbreaks—are forcing processors to prioritise cheese production over other dairy products.

To mitigate these challenges, producers are turning to technology to optimise production processes, minimise waste, and maintain profitability. Efficient supply chain management, combined with strategic use of automation and AI, is becoming a cornerstone of success in the sector.

Export Opportunities

The global market for cheese continues to grow, with regions such as North America, Asia, and the Middle East showing strong demand. European cheese exports are expected to rise modestly in 2025, driven by increased appetite for premium cheeses in international markets.

For UK producers, navigating post-Brexit trade complexities remains a challenge, but it also presents opportunities. By focusing on high-quality, value-added products, UK cheese producers can carve out a competitive position in the global marketplace.

Sustainability: A Growing Priority in Cheese Production

Sustainability has become a central concern for the cheese industry, influencing not only production methods but also packaging and marketing strategies. Consumers and regulators alike are demanding more environmentally responsible practices, and cheese producers are responding.

Sustainable Packaging Solutions

Packaging is a critical focus area in the sustainability conversation. Traditional cheese packaging often relies on materials like plastic, which are difficult to recycle and have a high environmental impact. In 2025, producers are increasingly adopting innovative, eco-friendly alternatives such as:

- Biodegradable Films: Made from renewable materials like cellulose, these films provide a sustainable option without compromising product protection.

- Recyclable Materials: Many producers are switching to fully recyclable packaging options, including paper-based wraps and recyclable plastics.

- Reusable Containers: For premium cheese products, reusable packaging solutions are emerging as a way to align with sustainability goals while enhancing the consumer experience.

Adopting sustainable packaging is not just an environmental imperative—it also aligns with consumer expectations. Surveys consistently show that eco-conscious packaging influences purchasing decisions, particularly among younger demographics.

Energy-Efficient Production

Cheese production is energy-intensive, and reducing carbon footprints is a key challenge for the industry. Many producers are investing in renewable energy sources, energy-efficient equipment, and waste reduction technologies to minimise their environmental impact. Solar panels, anaerobic digesters, and heat recovery systems are increasingly being integrated into production facilities.

Waste Reduction Initiatives

Food waste is another critical area of focus. Cheese producers are finding ways to repurpose by-products from the cheesemaking process, such as whey, into value-added products like protein powders or animal feed. This not only reduces waste but also creates additional revenue streams.

Labour Dynamics and Rising Costs

The UK’s post-2024 budget changes to National Insurance contributions and the continued rise in minimum wages are creating significant financial pressures for cheese producers. These shifts are driving innovation in labour management and accelerating the adoption of automation.

Automation as a Cost-Saving Measure

Higher labour costs are making automation an attractive option for many cheese producers. Automated equipment, from packaging machines to quality control systems, can reduce reliance on manual labour while improving efficiency and consistency. For example:

- Robotic cutting and slicing machines ensure precision and minimise waste.

- Automated packaging lines streamline production, increasing throughput while maintaining product integrity.

While the initial investment in automation can be high, the long-term cost savings and operational efficiencies often justify the expenditure. Producers who embrace automation are better equipped to remain competitive in a high-cost labour environment.

Upskilling the Workforce

As automation reduces the need for manual labour, it is creating demand for new skills. Cheese producers are increasingly investing in training programmes to upskill workers, equipping them with the expertise needed to manage and maintain advanced systems. Roles such as robotics technicians and quality data analysts are becoming integral to modern cheese production.

Opportunities and Challenges in Adoption

The transition to automation and sustainable practices offers immense potential but also poses challenges. High upfront costs, tight profit margins, and a lack of familiarity with advanced systems can deter investment. However, the long-term benefits—both financial and environmental—make these transitions worthwhile.

Sustainability as a Competitive Advantage

Sustainability is no longer a secondary concern—it is a competitive differentiator. Producers who adopt eco-friendly practices and communicate their sustainability efforts effectively are more likely to build brand loyalty and attract environmentally conscious consumers.

Balancing Costs and Benefits

While the benefits of automation and sustainable practices are clear, the cost of implementation can be a barrier, especially for smaller producers. Access to government grants, subsidies, and industry support can play a crucial role in enabling these transitions. Collaboration between industry stakeholders and policymakers will be essential for overcoming financial hurdles.

A Vision for the Future

The cheese industry in 2025 is navigating a period of rapid transformation. Advances in automation, AI, and robotics are reshaping production processes, while sustainability concerns are influencing every aspect of the supply chain. Rising labour costs and regulatory changes are adding further complexity, but they are also driving innovation.

For cheese producers willing to embrace change, these challenges represent an opportunity to build more efficient, resilient, and sustainable businesses. By focusing on premiumisation, adopting eco-friendly practices, and leveraging technology, the industry can meet the evolving demands of both consumers and regulators.

Conclusion

The cheese industry is at a pivotal moment. From sustainable packaging innovations to the adoption of automation and AI, the changes underway offer immense opportunities for growth and differentiation. However, success in this evolving landscape requires vision, adaptability, and a willingness to invest in the future.

As the industry continues to evolve, collaboration and innovation will be key to unlocking its full potential. What steps is your business taking to address these trends?

Let’s connect and discuss how we can shape the future of the cheese industry together!

You can now read the most important #news on #eDairyNews #Whatsapp channels!!!

🇺🇸 eDairy News INGLÊS: https://whatsapp.com/channel/0029VaKsjzGDTkJyIN6hcP1K